Building a better chemical factory—out of microbes

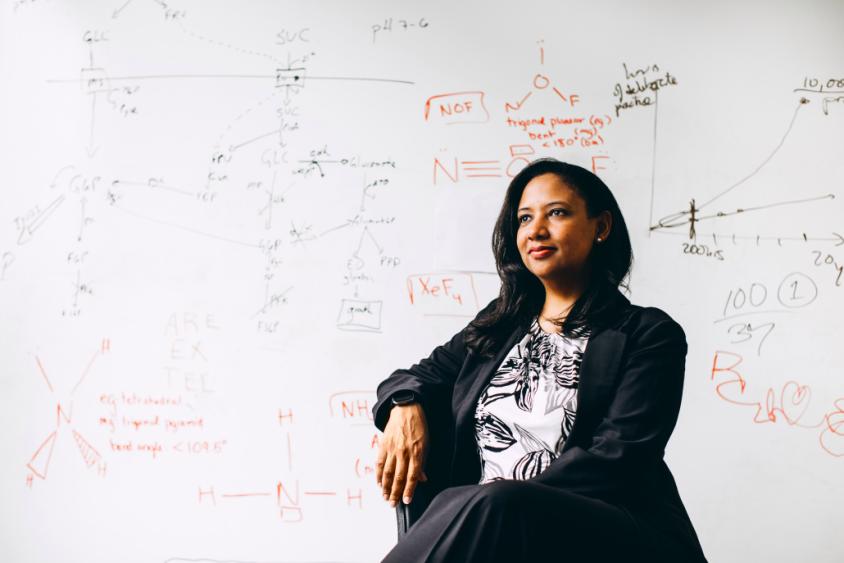

Photo by Sasha Israel

Professor Kristala Jones Prather ’94 has made it practical to turn microbes into efficient producers of desired chemicals. She’s also working to reduce our dependence on petroleum.

Metabolic engineers have a problem: cells are selfish. The scientists want to use microbes to produce chemical compounds for industrial applications. The microbes prefer to concentrate on their own growth.

Kristala L. Jones Prather ’94 has devised a tool that satisfies both conflicting objectives. Her metabolite valve acts like a train switch: it senses when a cell culture has reproduced enough to sustain itself and then redirects metabolic flux—the movement of molecules in a pathway—down the track that synthesizes the desired compound. The results: greater yield of the product and sufficient cell growth to keep the culture healthy and productive.

William E. Bentley, a professor of bioengineering at the University of Maryland, has been following Prather’s work for more than two decades. He calls the valves “a new principle in engineering” that he anticipates will be highly valued in the research community. Their ability to eliminate bottlenecks can prove so essential to those attempting to synthesize a particular molecule in useful quantities that “in many cases it might decide whether it is a successful endeavor or not,” says Bentley.

Prather, MIT’s Arthur D. Little Professor of Chemical Engineering, labors in the intersecting fields of synthetic biology and metabolic engineering: a place where science, rather than art, imitates life. The valves play a major role in her larger goal of programming microbes—chiefly E. coli—to produce chemicals that can be used in a wide range of fields, including energy and medicine. She does that by observing what nature can do. Then she hypothesizes what it should be able to do with an assist from strategically inserted DNA.

“We are increasing the synthetic capacity of biological systems,” says Prather, who made MIT Technology Review’s TR35 list in 2007. “We need to push beyond what biology can naturally do and start getting it to make compounds that it doesn’t normally make.”

Prather describes her work as creating a new kind of chemical factory inside microbial cells—one that makes ultra-pure compounds efficiently at scale. Coaxing microbes into producing desired compounds is safer and more environmentally friendly than relying on traditional chemical synthesis, which typically involves high temperatures, high pressures, and complicated instrumentation—and, often, toxic by-products. She didn’t originate the idea of turning microbes into chemical factories, but her lab is known for developing tools and fine-tuning processes that make it efficient and practical.

That’s the approach she has taken with glucaric acid, which has multiple commercial applications, some of them green. Water treatment plants, for example, have long relied on phosphates to prevent corrosion in pipes and to bind with metals like lead and copper so they don’t leach into the water supply. But phosphates also feed algae blooms in lakes and oceans. Glucaric acid does the same work as phosphates without feeding those toxic blooms.

Producing glucaric acid the usual way—through chemical oxidation of glucose—is expensive, often yields product that isn’t very pure, and creates a lot of hazardous waste. Prather’s microbial factories produce it with high levels of purity and without the toxic by-products, at a reasonable cost. She cofounded the startup Kalion in 2011 to put her microbial-factory approach into practice. (Prather is Kalion’s chief science officer. Her husband, Darcy Prather ’91, is its president.)

The company, which is lining up large-scale production in Slovakia, has several prospective customers. Although the largest of these are in oil services, “it also turns out, in the wonderful, wacky way chemistry works, that the same compound is used in pharmaceutical manufacturing,” Prather says. It’s required, for example, in production of the ADHD drug Adderall. And it can be used to make textiles stronger, which could lead to more effective recycling of cotton and other natural materials.

Kalion’s first target is phosphates, because of their immediate commercial applications. But in her wider research, Prather has also drawn a great big bull’s-eye on petroleum. Eager to produce greener alternatives to gasoline and plastics, she and her research group at MIT are using bacteria to synthesize molecules that would normally be derived from petroleum. “Big picture, if we are successful,” Prather says, “what we are doing is moving things one by one off the shelf to say, ‘That no longer is made from petroleum. That now is made from biomass.’”

From East Texas to MIT

Born in Cincinnati, Prather grew up in Longview, Texas, against a backdrop of oilfield pumps and derricks. Her father died before she turned two. Her mother worked at Wylie College, a small, historically Black school—and earned a bachelor’s degree there herself in 2004, Prather is quick to add.

Her high school’s first valedictorian of color, Prather had only vague ideas about academic and professional opportunities outside her state. With college brochures flooding the family’s mailbox in her junior year, she sought advice from a history teacher. “Math was my favorite subject in high school, and I was enjoying chemistry,” says Prather. The teacher told her that math plus chemistry equaled chemical engineering, and that if she wanted to be an engineer she should go to MIT. “What’s MIT?” asked Prather.

Others in the community were no better informed. What was then the DeVry Institute of Technology, a for-profit school with a less-than-stellar academic reputation and campuses around the country, was advertising heavily on television. When she told people she was going to MIT, they assumed it was a DeVry branch in Massachusetts. “They were disappointed, because they thought I was going to do great things,” says Prather. “But here I was going to this trade school to be a plumber’s assistant.”

In June 1990 Prather arrived on campus to participate in Interphase, a program offered through MIT’s Office of Minority Education. Designed to ease the transition for incoming students, Interphase “was a game-changer,” says Prather. The program introduced her to an enduring group of friends and familiarized her with the campus. Most important, it instilled confidence. Coming from a school without AP classes, Prather had worried about starting off behind the curve. When she found she knew the material in her Interphase math class, it came as a relief. “When I was bored, I thought, ‘I belong here,’” she says.

As an undergraduate Prather was exposed to bioprocess engineering, which uses living cells to induce desired chemical or physical changes in a material. At that time scientists treated the cells from which the process starts as something fixed. Prather became intrigued by the idea that you could engineer not only the process but also the biology of the cell itself. “The way you could copy and cut and paste DNA appealed to the part of me that liked math,” she says.

After graduating in 1994, Prather got her PhD at the University of California, Berkeley, where her advisor was Jay Keasling, a professor of chemical and biomolecular engineering who was at the forefront of the new field of synthetic biology. At Berkeley, Prather sought ways to move DNA in and out of cells to optimize the creation of desirable proteins.

The practice at that time was to bulk up cells with lots of DNA, which would in turn produce lots of protein, which would generate lots of the desired chemical compound. But there was a problem, which Prather—who lives near a scenic state park—explains with a local analogy. “I can go for a light hike in the Blue Hills Reservation,” she says, “but not if you put a 50-pound pack on my back.” Similarly, an overloaded cell “can sometimes respond by saying, ‘I am too tired.’” Prather’s doctoral thesis explored systems that efficiently produce a lot of a desired chemical using less DNA.

In her fourth year at Berkeley, Prather received a fellowship from DuPont and traveled to Delaware for her first full-length presentation. Following standard conference practice, she laid out for her audience the three motivations underlying her research. Afterward, one of the company’s scientists politely explained to her why all three were misguided. “He said, ‘What you are doing is interesting and important, but you are motivated by what you think is important in industry,’” says Prather. “‘And we just don’t care about any of that stuff.’”

Humbled, Prather decided a sojourn in the corporate world would reduce the risk that her academic career would be consigned to real-world irrelevance. She spent the next four years at Merck, in a group developing processes to make things like therapeutic proteins and vaccines. There she learned about the kinds of projects and problems that matter most to practitioners like her DuPont critic.

Merck employed hordes of chemists to produce large quantities of chemical compounds for use in new drugs. When part of that process seemed better suited to biology than to chemistry, they would hand it off to the department Prather worked in, which used enzymes to perform the next step. “They were typically not very complicated reactions,” says Prather. “A single step converting A to B.”

Prather was intrigued by the possibility of performing not just individual steps but the entire chemical synthesis within cells, using chains of reactions called metabolic pathways. That work inspired what would become some of her most acclaimed research at MIT, where she joined the faculty in 2004.

Finding the production switch

It wasn’t long after returning to MIT that this young woman from the Texas oil patch took aim at fossil fuels and their by-products. Many of her lab’s projects focus on replacing petroleum as a feedstock. In one—a collaboration with MIT colleagues Brad Olsen ’03, a chemical engineer, and Desiree Plata, PhD ’09, a civil and environmental engineer—Prather is using biomass to create renewable polymers that could lead to a greener kind of plastic. Her lab is figuring out how to induce microbes to convert sugar from plants into monomers that can then be chemically converted into polymers to create plastic. At the end of the plastic’s usable life, it biodegrades and turns back into nutrients. Those nutrients “will give you more plants from which you can extract more sugar that you can turn into new chemicals to go into new plastics,” says Prather. “It’s the circle of life there.”

These days she is drawing the most attention for her research in optimizing metabolic pathways—research that she and other scientists can then use to maximize the yield of a desired product.

The challenge is that cells prioritize the use of nutrients, such as glucose, to grow rather than to manufacture these desirable compounds. More growth for the cell means less product for the scientist. “So you run into a competition problem,” says Prather.

Take glucaric acid, the chemical produced by Prather’s company—and one that Keasling says is extremely important to industry. (“These molecules are not trivial to produce, particularly at the levels that are needed industrially,” he says.) Prather and her lab had been adding three genes—drawn from mice, yeast, and a bacterium—to E. coli, enabling the bacteria to transform a type of simple sugar into glucaric acid. But the bacteria also needed that sugar for a metabolic pathway that breaks down glucose to feed its own growth and reproduction.

Prather’s team wanted to shut down the pathway nourishing growth and divert the sugar into a pathway producing glucaric acid—but only after the bacterial culture had grown enough to sustain itself as a productive chemical factory. To do so they used quorum sensing, a kind of communication through which bacteria share information about changes in the number of cells in their colony, which allows them to coordinate colony-wide functions such as gene regulation. The team engineered each cell to produce a protein that then creates a molecule called AHL. When quorum sensing detects a certain amount of AHL—the amount produced in the time it takes for the culture to reach a sustainable size—it activates a switch that turns off production of an enzyme that is part of the glucose breakdown process. The glucose shifts to the chemical-synthesis pathway, greatly increasing the amount of glucaric acid produced.

Prather’s switches, called metabolite valves, are now used in processes that harness microbes to produce a wide range of desired chemicals. The valves open or close in response to changes in the density of particular molecules in a pathway. These switches can be fine-tuned to optimize production without compromising the health of the bacteria, dramatically increasing output. The researchers’ flagship paper, which was published in Nature Biology in 2017, has been cited almost 200 times. The goal at this point is to step up the scale.

Like many of the mechanisms Prather uses in her research, such switches already exist in biology. Cells whose resources are threatened by neighboring foreign cells will switch from growth mode to producing antibiotics to kill off their competitors, for example. “Cells that make things like antibiotics have a natural way of first making more of themselves, then putting their resources into making product,” she says. “We developed a synthetic way of mimicking nature.”

Prather’s Berkeley advisor, Keasling, has been using a derivative of the switch inspired by her research. “The tool for channeling metabolic flux—the flow of material through a metabolic pathway—is super-important work that I think will be widely used in the future by metabolic engineers,” he says. “When Kristala publishes something, you know it is going to work.”

“She cares deeply about education and is invested in her students in a way that really stands out,” says Keasling.

Mentoring young scientists

Prather receives at least as much recognition for teaching and mentoring as for her research. “She cares deeply about education and is invested in her students in a way that really stands out,” says Keasling. Students describe her optimism and supportiveness, saying that she motivates without commanding. “She created an environment where I was free to make my own mistakes and learn and grow,” says Kevin V. Solomon, SM ’08, PhD ’12, who studied with Prather between 2007 and 2012 and is now an assistant professor of chemical and biomedical engineering at the University of Delaware. In some other labs, he notes, “you have hard deadlines, and you perform or you freak out.”

It was at Merck that Prather realized how much she loves working with young scientists—and it was also where she assembled the management arsenal she uses to run her lab. So, for example, she makes sure to get to know each student’s preferences about communication style, because “treating everyone fairly is not the same as treating everyone the same,” she says. One-on-one meetings commence with a few minutes of chat about general topics, so Prather can suss out students’ states of mind and make sure they are okay. She sets clear standards, intent on avoiding the uncertainty about expectations that is common in academic labs. And when students do raise concerns, “it is important to document and confirm that they have been heard,” she says.

The most effective leaders model the behaviors they want to see in others. Prather, who received MIT’s Martin Luther King Leadership Award in 2017, expects commitment and high performance from her grad students and postdocs, but not at the cost of their physical or mental health. She discourages working on weekends—to the extent that is possible in biology—and insists that lab members take vacations. And from the beginning she has demonstrated that it is possible to simultaneously do first-class science and have a personal life.

Read the full article on Technology Review.